Brands

Nikkiso Cryoquip

About the Company

Nikkiso Cryoquip, a Cryogenic Industries Company, is the world’s leading fabricators of cryogenic vaporizers and industrial gas equipment. Nikkiso Cryoquip’s capabilities span the entire spectrum of cryogenic equipment from the fabrication of cold boxes used to manufacture the liquefied gases themselves to equipment that stores and uses the gases in a multitude of applications.

Our History

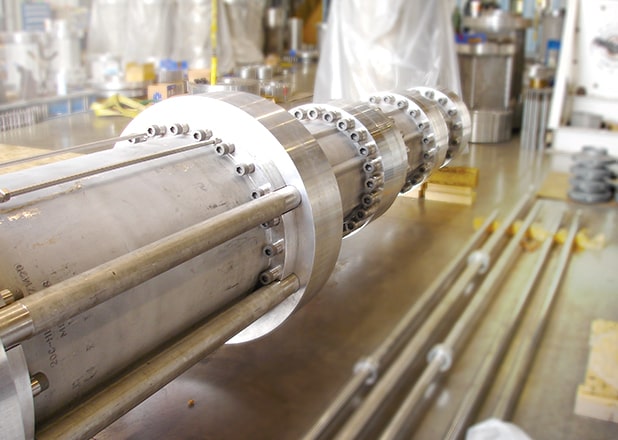

Over the years Nikkiso Cryoquip has manufactured hydrogen PSA valve skids; liquid nitrogen based equipment for the cleaning of electronic and optical components; gas recycling and separation equipment; specialized exotic cryogenic gas storage tanks; high flow vaporization equipment for wind tunnel applications; small capacity cryogenic storage tanks; hydrocarbon process skids; industrial gas drying skids; pressure swing adsorption gas manufacturing plants; solvent recovery systems; pre-treatment modules and cold boxes for air separation plants; medical and pharmaceutical application equipment, LNG liquefaction plants, LNG conditioning vaporizers for filling stations and heat exchangers made from exotic material such as SS310, Hastelloy and Inconel.

Nikkiso Cryoquip is the world’s leading manufacturer of cryogenic ambient air natural and forced draft all aluminum vaporizers. Nikkiso Cryoquip has manufactured thousands of cryogenic ambient, electric, fuel-fired, steam and water bath vaporizer systems which are currently in service in countries throughout the world.

These cryogenic vaporizers are in service vaporizing cryogenic fluids such as LNG, LPG, ethylene, oxygen, nitrogen, argon, hydrogen, CO2, methane, boron, ammonia, helium and other exotic gases.